Commercial Bins

This Sioux Steel bin is by far the most well-built & heaviest duty bin we've got here. In our business, we load & unload, load & unload so you want something that's going to take stress. And I think they've got that.

Lyman Hanson, Hazel Farmers Elevator, Hazel, SD

We did a lot of looking before deciding on the Sioux bins. I've got some other brands of bins at my operation and after looking at the Sioux commercial bin, the decision was simple. We were impressed with the gross weight of the Sioux bins, the way they designed the doors, the manhole on top and the strength of the roof. The decision to go with Sioux was a no brainer for us.

Chris Nelsen, Yankton, SD

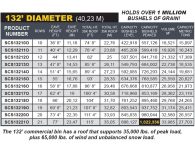

1 Million Bushel Commercial Grain Storage

Technology and innovation change the grain storage and handling industry each year. We work hard to ensure every component of your bin is tested to withstand the most rigorous conditions. Sioux Steel commercial bins are engineered using the latest technology for your grain storage needs, while offering features that reinforce your confidence.

Commercial Bin Features

- Roofs are available with up to 50,000 lb. peak load.

- 70 lb/bushel or 64 lb/bushel systems.

- 2 to 3 stiffeners per side wall sheet.

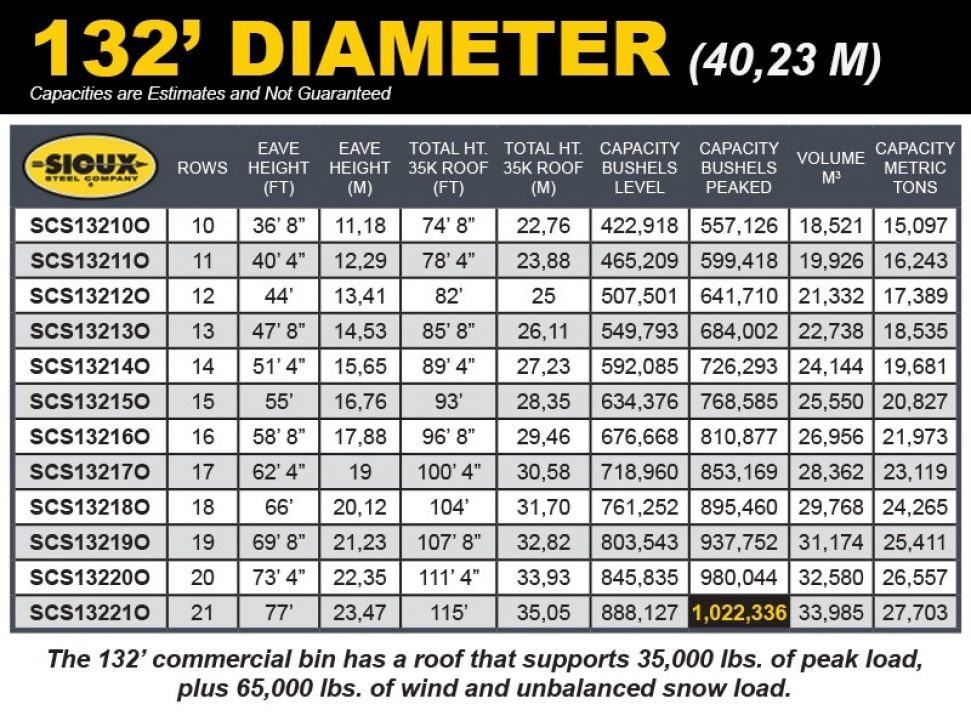

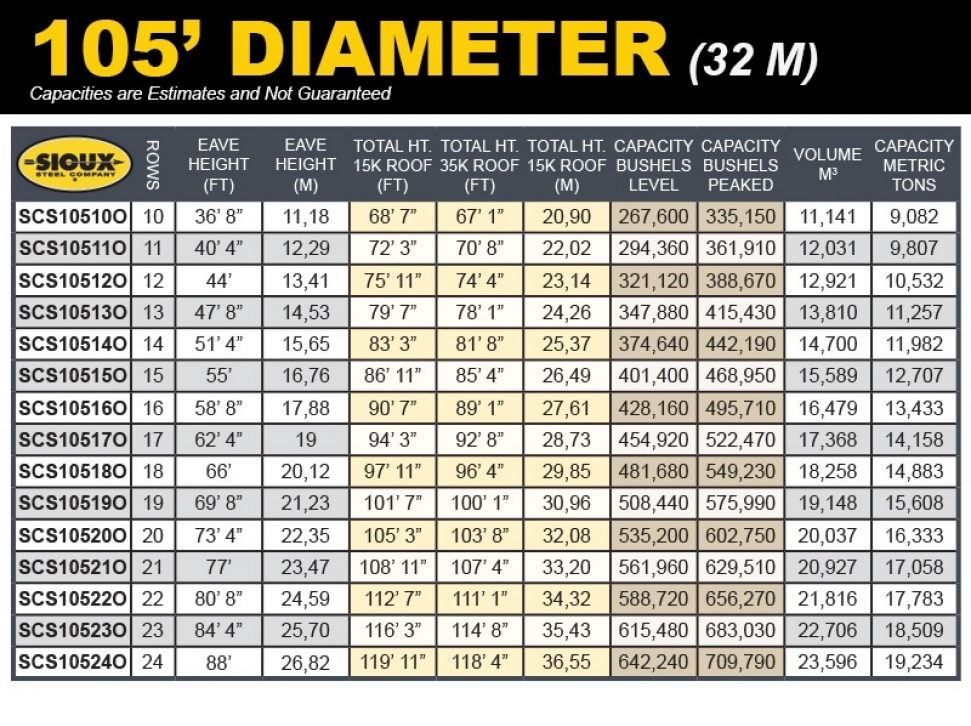

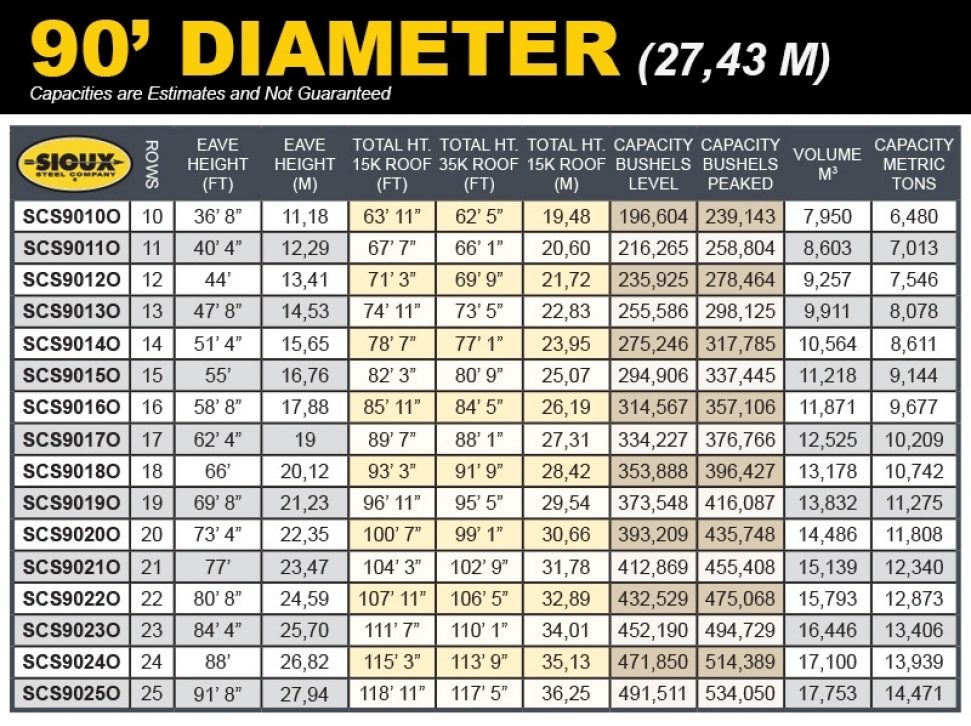

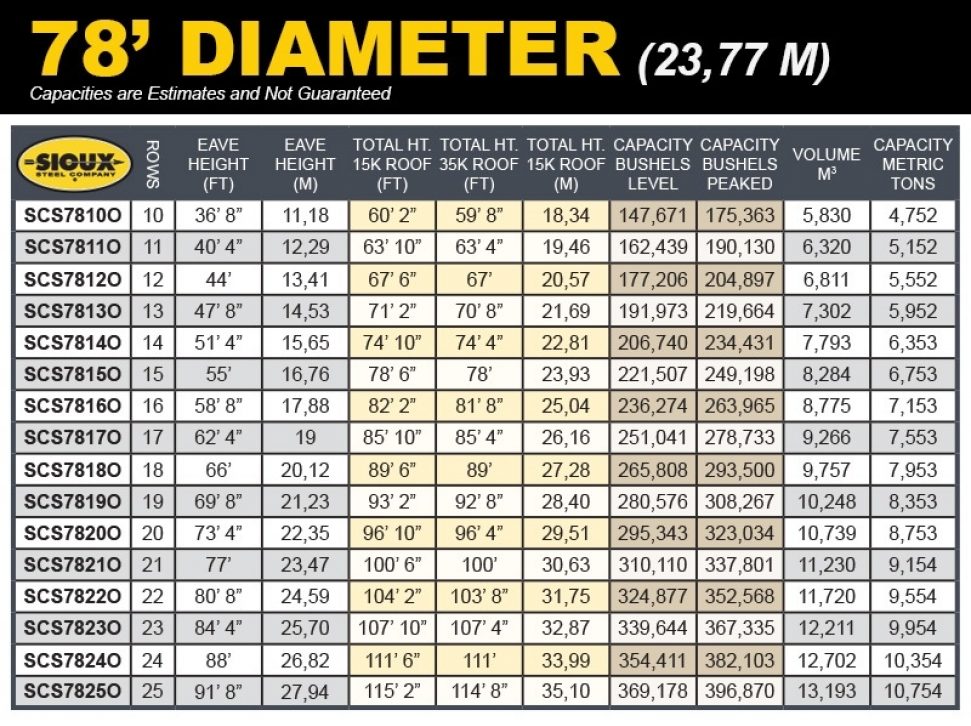

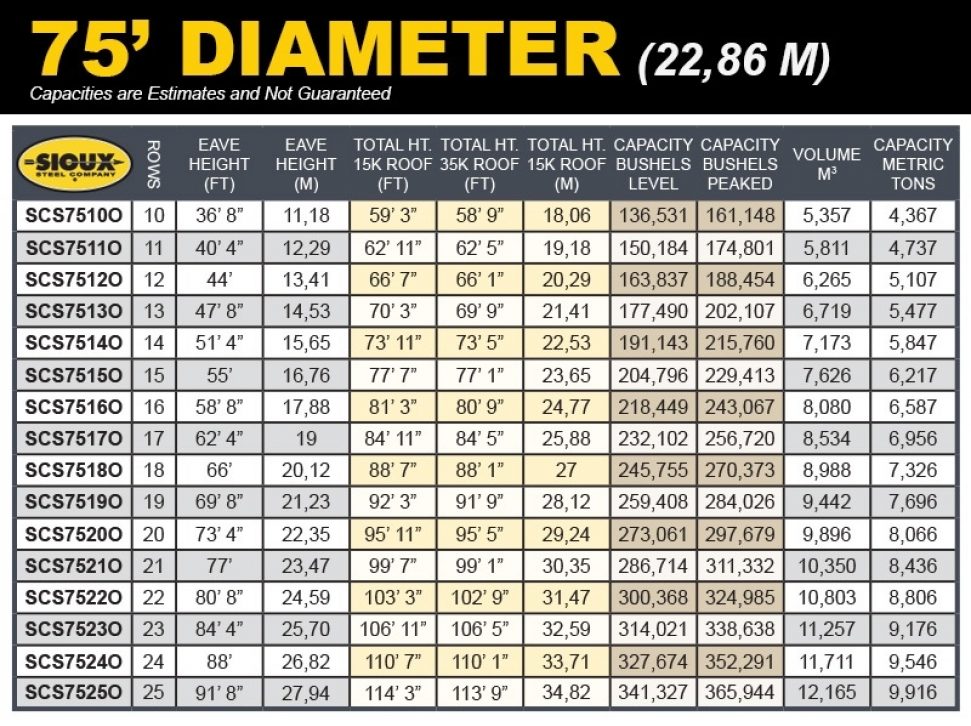

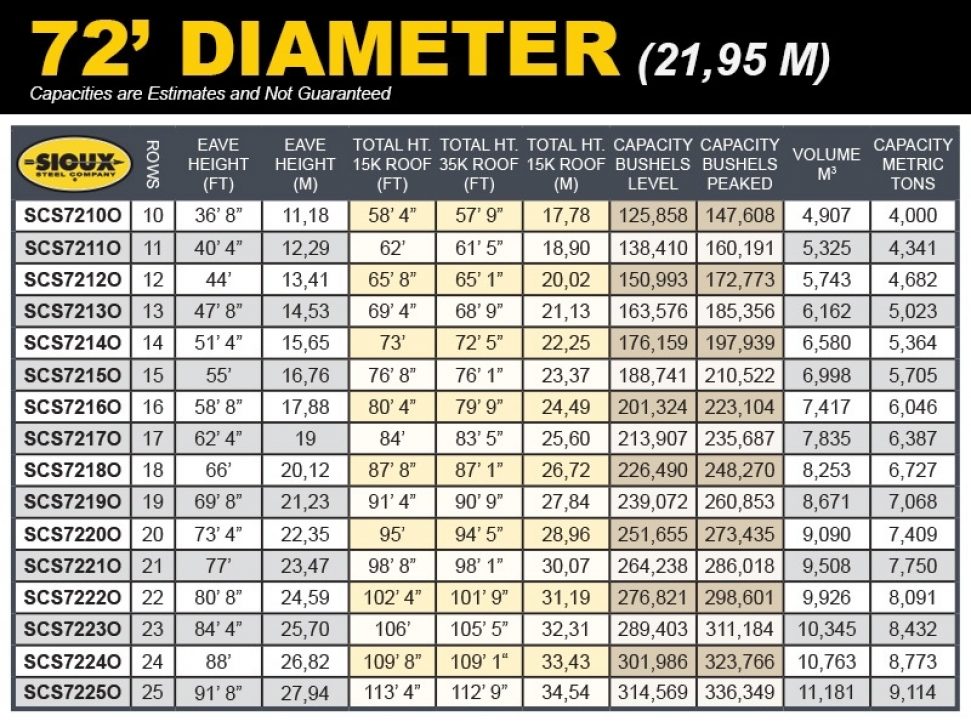

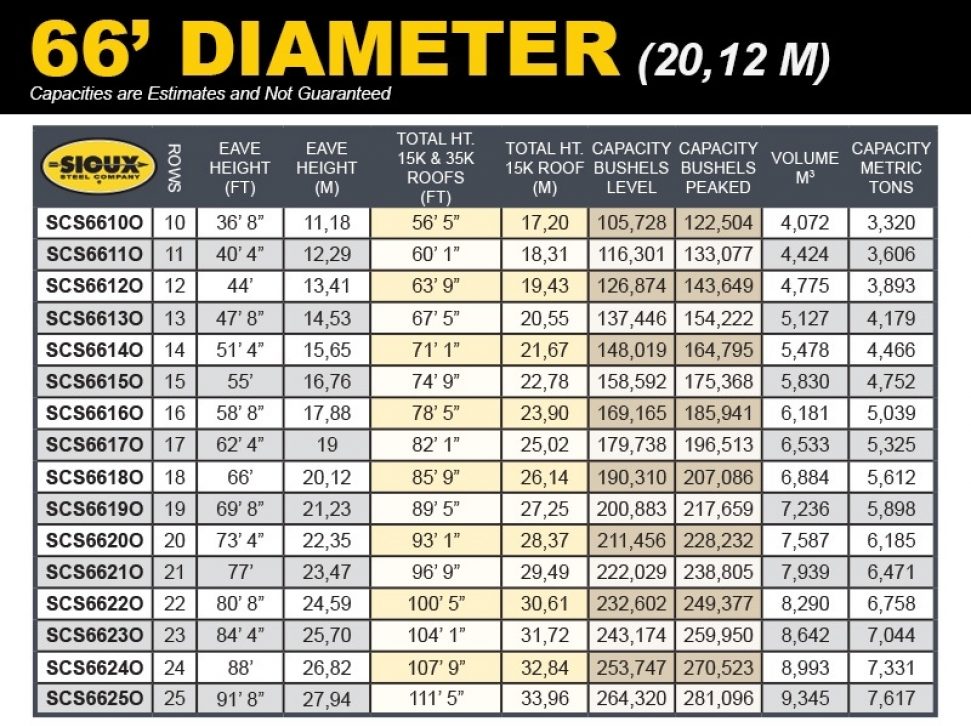

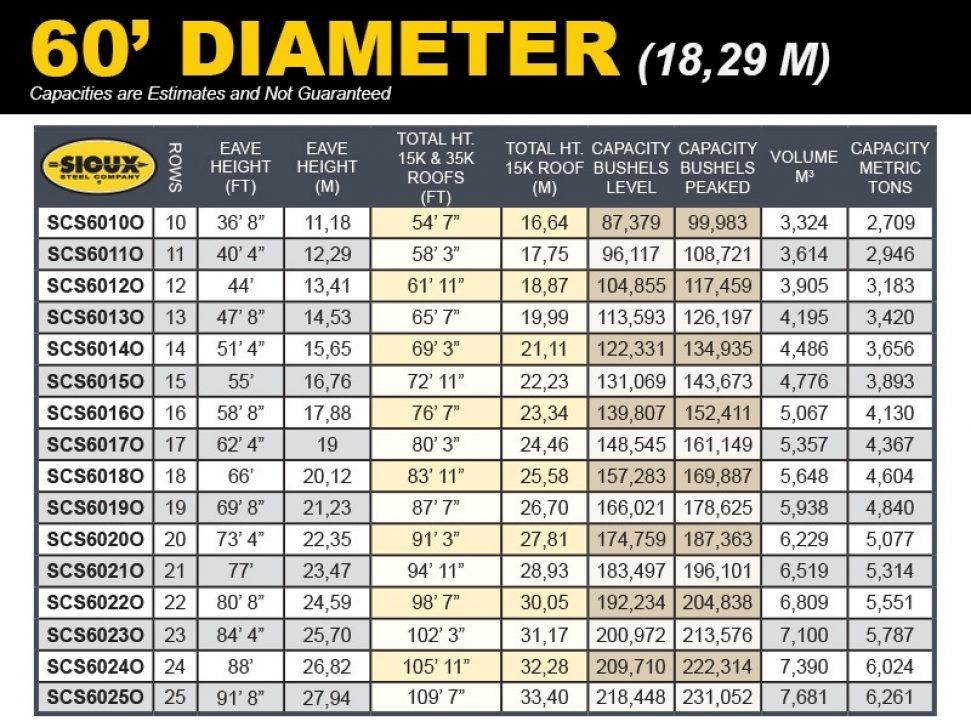

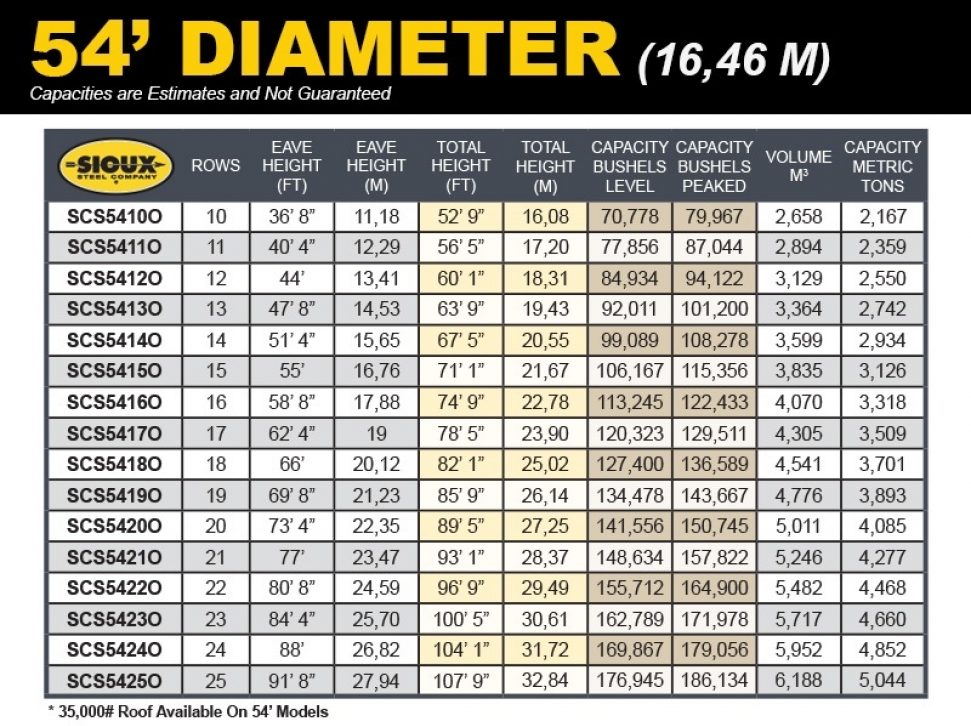

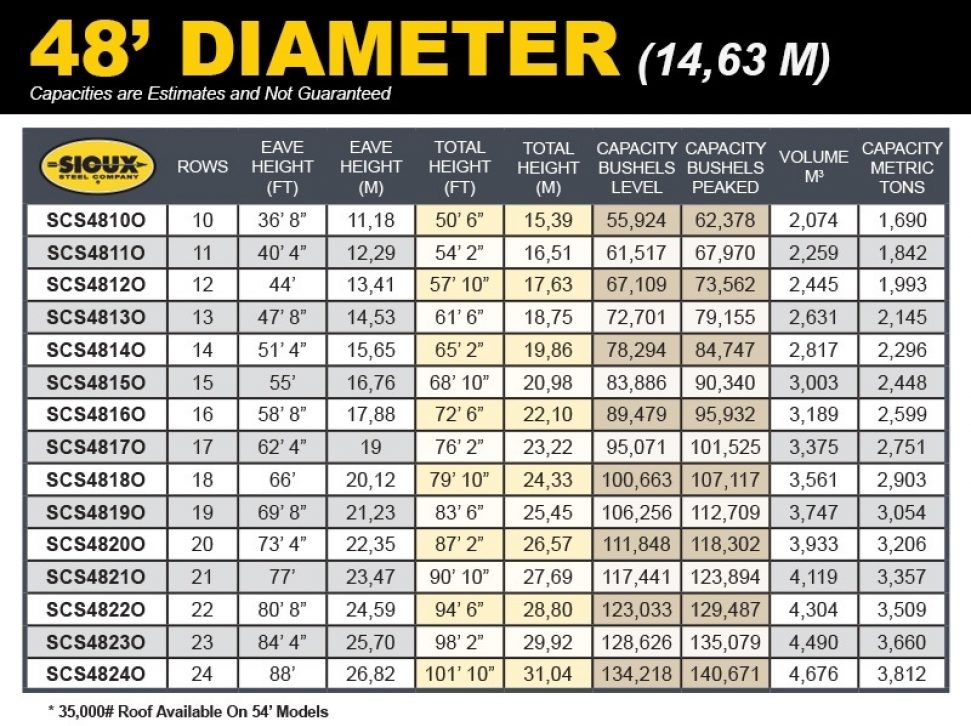

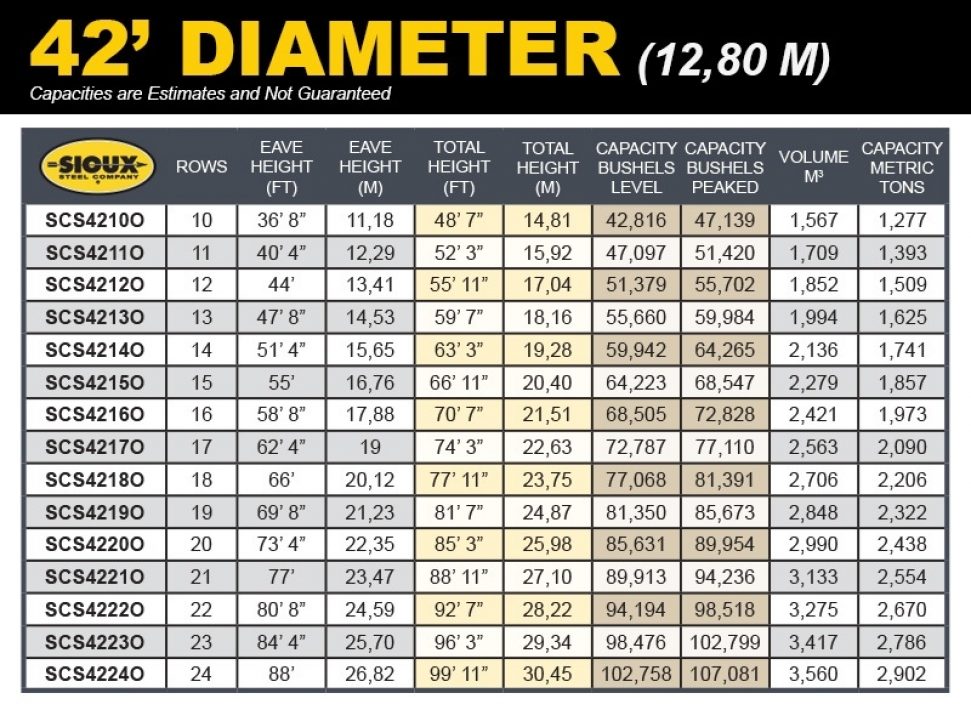

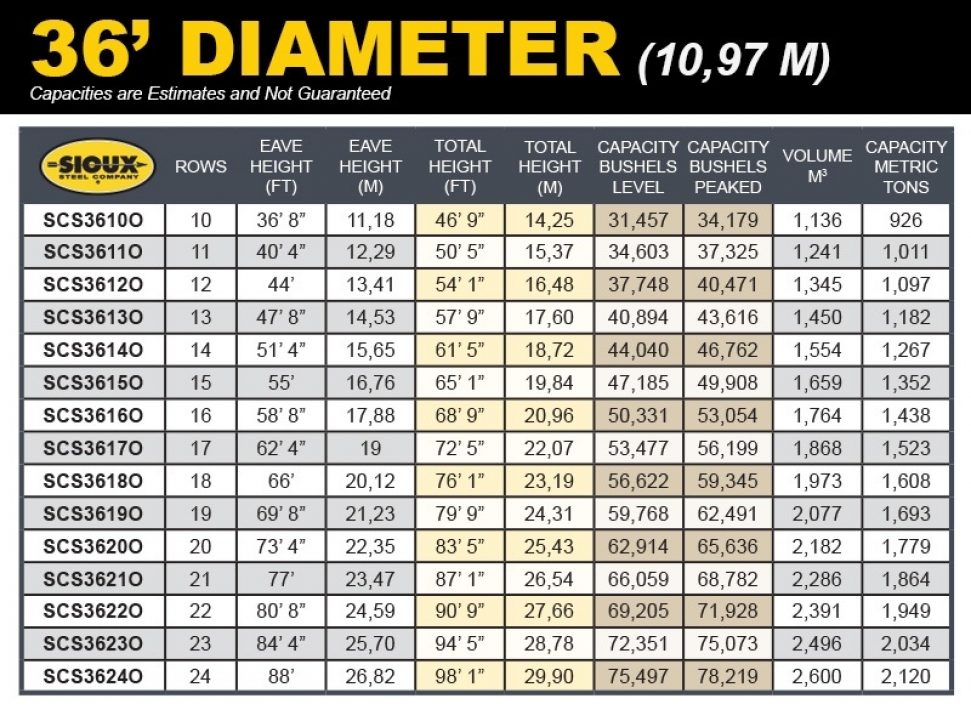

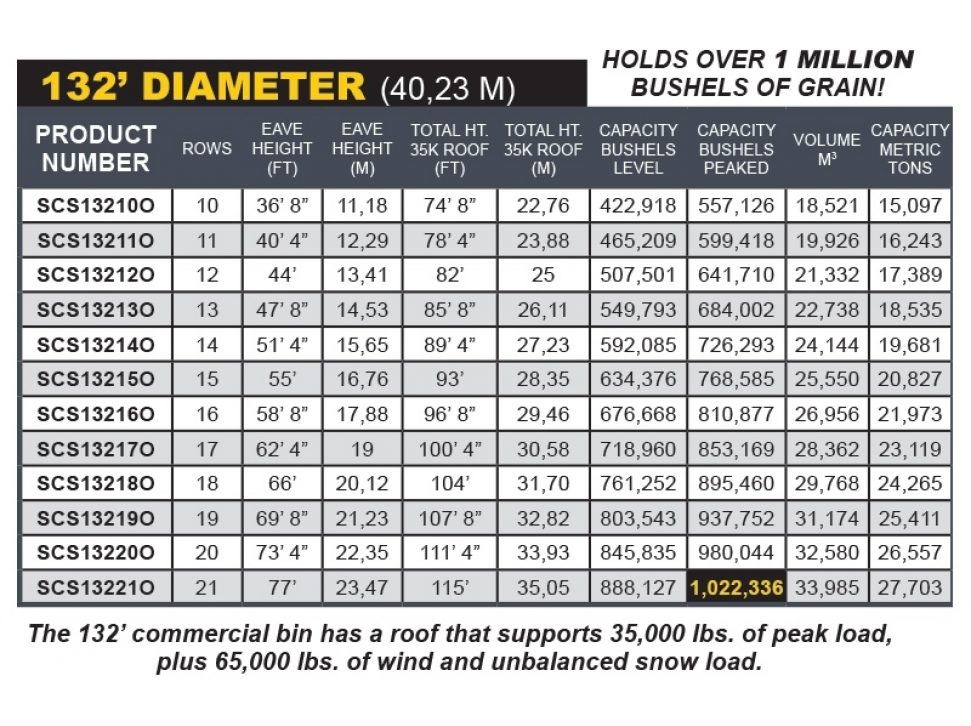

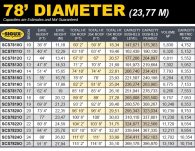

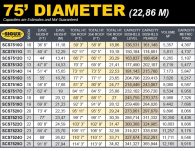

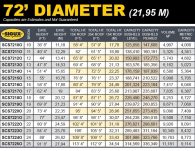

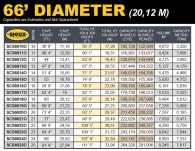

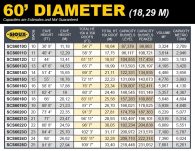

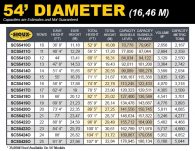

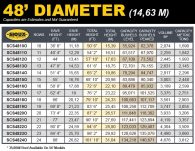

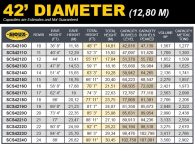

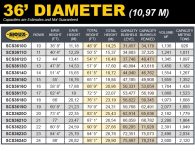

Commercial Sizes and Specifications

Capacities are calculated at 28 degree angle of repose (grain 1” below eave), based on ASAE Standard: S413.1 and include 6% compaction. All bins are designed for storage of grain and/or free flowing materials not exceeding 51 lb/ft3 (55 lb/ft3 including compaction). Storage of grains heavier than 55 lbs per cubic foot (including compaction), must be approved by Sioux Steel.

- Other sizes available.

- Total height based upon standard 60" flat cap.

- We reserve the right to change specifications without notice.

Increasing Grain Weights

Test weights of grains have increased over the last decade due to new hybrids and genetics. An average of 60 lb. per bushel corn, 60 lb. per bushel wheat and soybeans range in the 55 lb. to 60 lb. range. Grain storage facilities need to account for these increased test weights in the engineering of their grain storage equipment.

Systems To Choose From

64 LB/Bushel Bins (18 - 132’ diameter bins)

- 2 or 3 stiffeners per side wall sheet on stiffened bins.

- Designed for free flowing grains up to 64 lb/bushel (51 lbs/ft3).

- 4” corrugation and 70,000 psi tensile strength (55,000 psi yield strength) steel.

- Filled up to 20,000 (550 MT/hour) bushels per hour and unloaded at 25,000 (700 MT/hour) bushels per hour.

70 LB/Bushel Bins (90’, 105’, & 132’ diameter bins)

- 3 stiffeners per side wall sheet.

- Designed for free flowing grains up to 70 lb/bushel (56 lbs/ft3).

- 4” corrugation and 70,000 psi tensile strength (55,000 psi yield strength) steel.

- Filled up to 20,000 (550 MT/hour) bushels per hour and unloaded at 25,000 (700 MT/hour) bushels per hour.

Sidewall Strength

Wind Rings

Wind rings offer additional strength against the elements. External pressure from wind forces are overcome by utilizing wind rings to help equalize the hoop strength. Design and quantity of wind rings are determined by diameter and height of bin to adequately handle the external forces of wind.

Defined Bolt Pattern

Sioux Steel bins are designed to handle the stresses associated with 64 lb/bushel & 70 lb/bushel grain weights. Bolt patterns are optimized for each connection depending on the amount of hoop tension and the gauge of the side wall sheet being used. This results in strong yet efficient vertical and horizontal bolt seams.

Strongest Stiffener Splices

Stiffener splices ensure that the large vertical loads are transferred properly between stiffener sections. Sioux bins use both an insert and two back plates at stiffener splices. We utilize 7/16” hardware in all wall sheet seams and at all stiffener to wall sheet connections. 7/16” fasteners are 36% stronger than 3/8”.

Base Angle for Single Pass Sweeping

Heavy base angles are installed between the stiffener base plates and are secured to the bottom horizontal holes in the bottom sheet. This results in a robust connection between the bin and the foundation. The base angles have holes in them for additional anchor bolts. The additional anchor bolts are required to resist the high lateral and uplift loads created when sweeping larger diameter bins in a single pass. These angles are standard on bins 72’ and larger in both two and three stiffener per sheet configurations.

Ease of Construction

Combining 44 inch sheets and 3 roof panels per single sheet lessens the demand for bolts, nuts and washers which, in turn, lowers weight and erection costs.

Anchor System and Shims

The base plate and shim system on Sioux Steel commercial bins ensure stability and solid load path. Together they form a firm and permanent foundation with maximum strength.

Roofs

Sioux Steel roof structures are designed for up to 50,000 lbs. of peak load and utilize galvanized back to back “C” channels for ultimate strength. The large flat tops, varying in diameter from 5’ to 12’, provide multiple connection points to support catwalks and equipment loads.

Find more information about Commercial Grain Bin Roofs.

Access Points

Man-Way

The unique ovate construction of the man-way is the largest and most "user friendly" in the industry. It is designed to allow access to a heavily clothed individual.

Access Door

Four doors designed specifically for strength and integrity dependent on the diameter and height of the structure. All feature tieless inside panels, secure latching and a large 36” x 27” opening.

Walk-In Doors

Large 1-tier & 1-1/2 tier door options are available. The industry's LARGEST 1-1/2 tier door. 27” x 58” tall openings.

Floors

Full Floor and Flush Floor

Designs range from a variety of in-concrete systems to full floor using 16, 18 or 20 gauge planking formulated by height and diameter. Choose from a welded free flow system of supports or 17 gauge die cast supports.

Floor Designs

A variety of floor systems are available from full floors above concrete with custom plenum heights, to flush in concrete patterns designed for your installation. Sioux Steel Company can also provide hopper bottom aeration systems for concrete hopper foundations or steel commercial hopper bottom tanks. Find more information about floors.